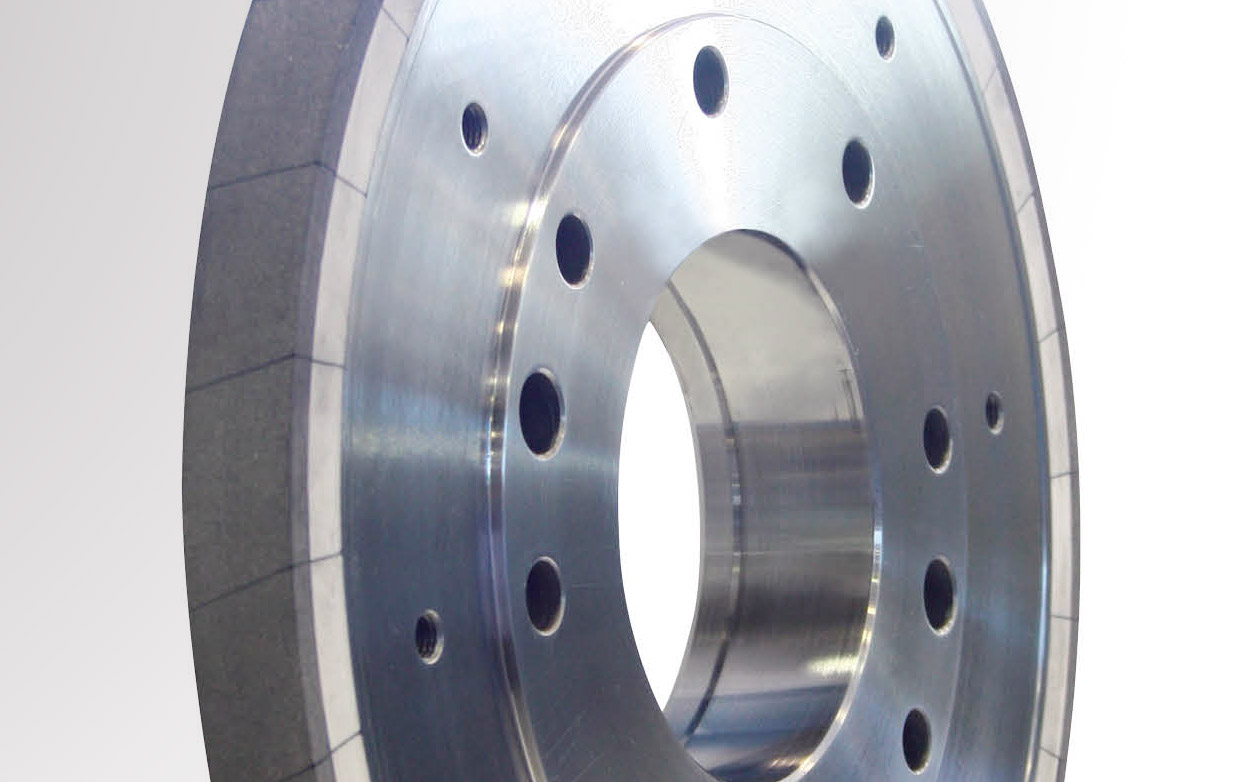

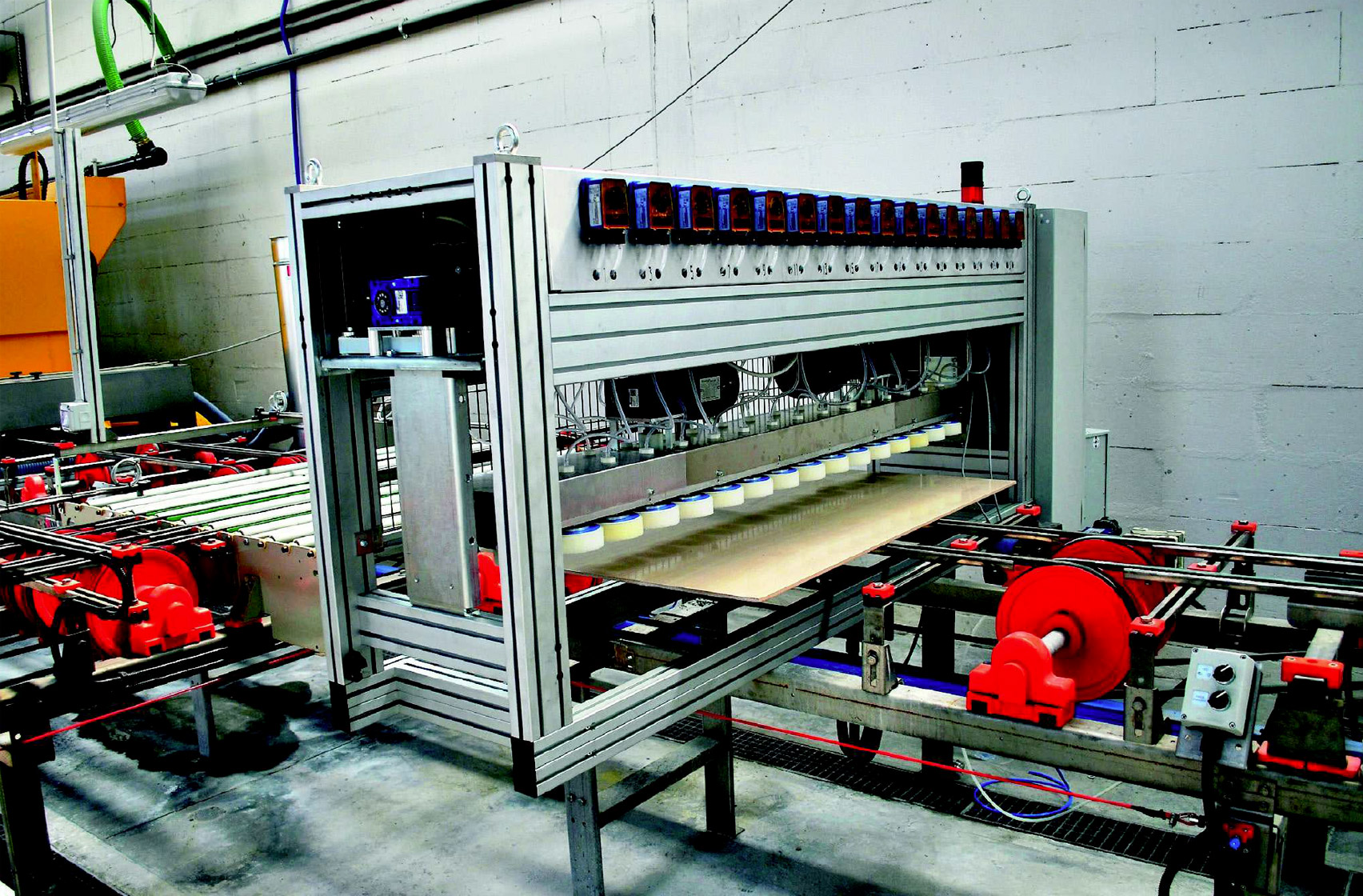

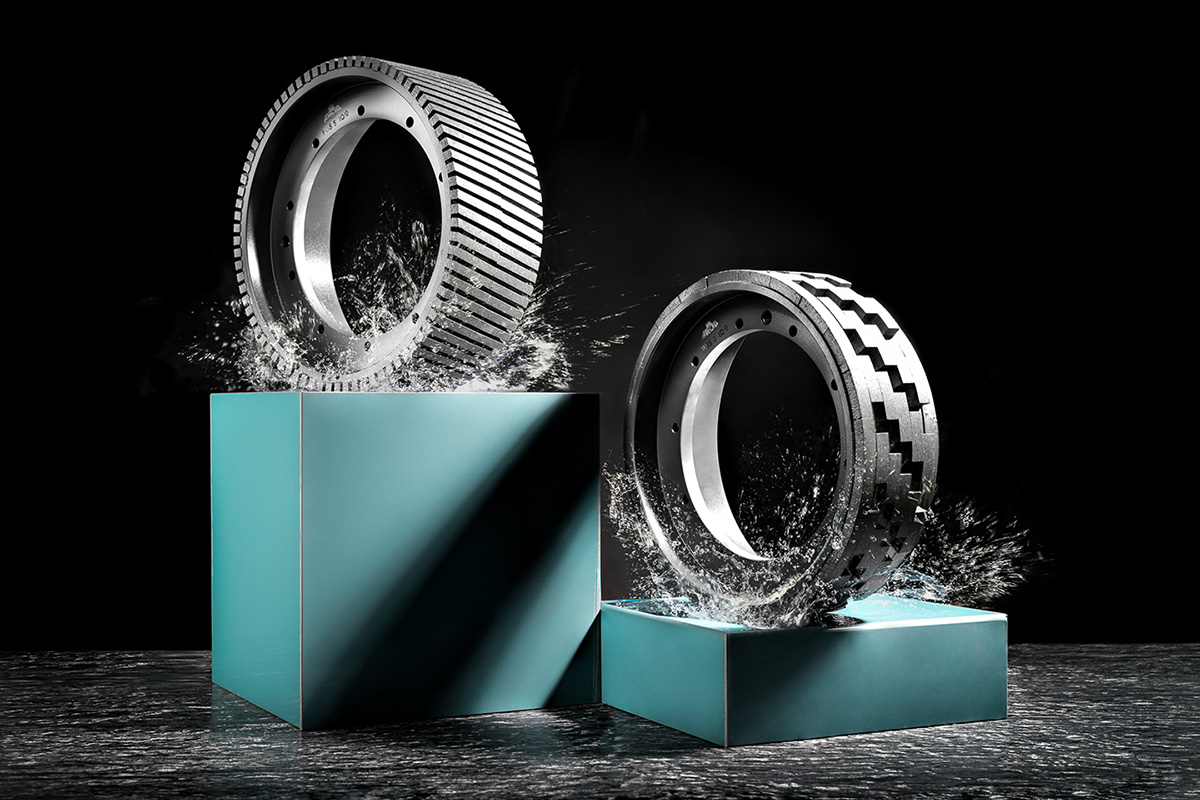

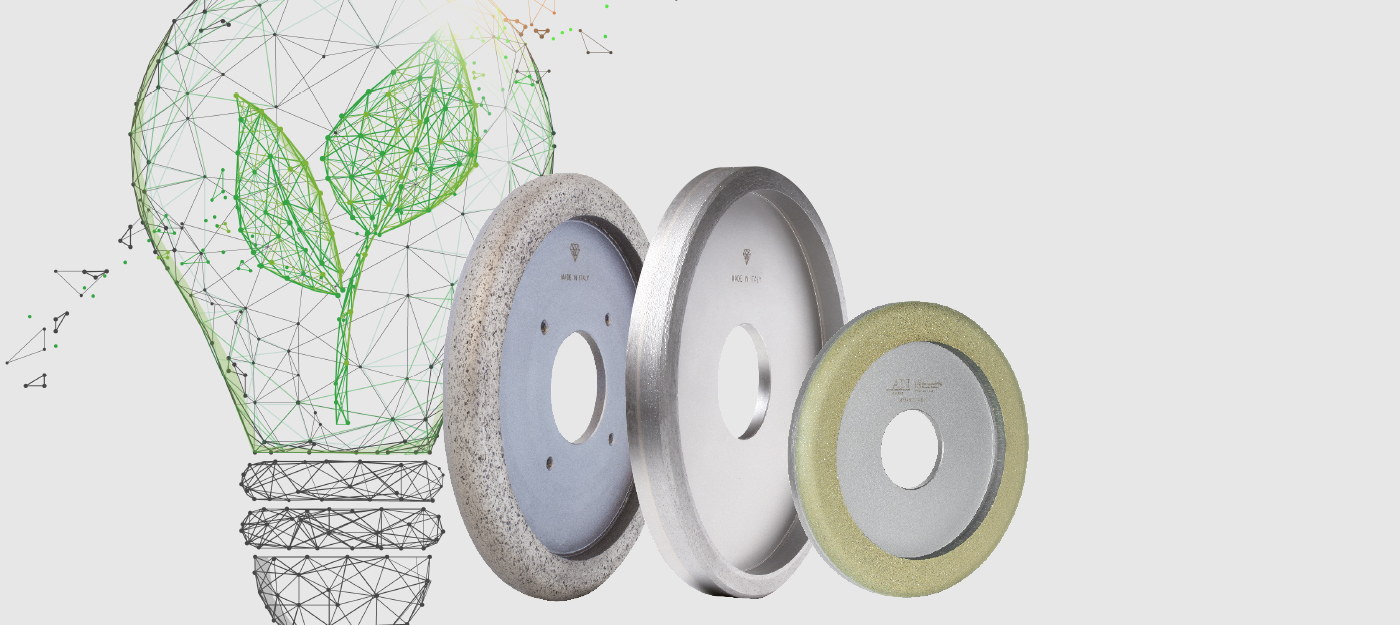

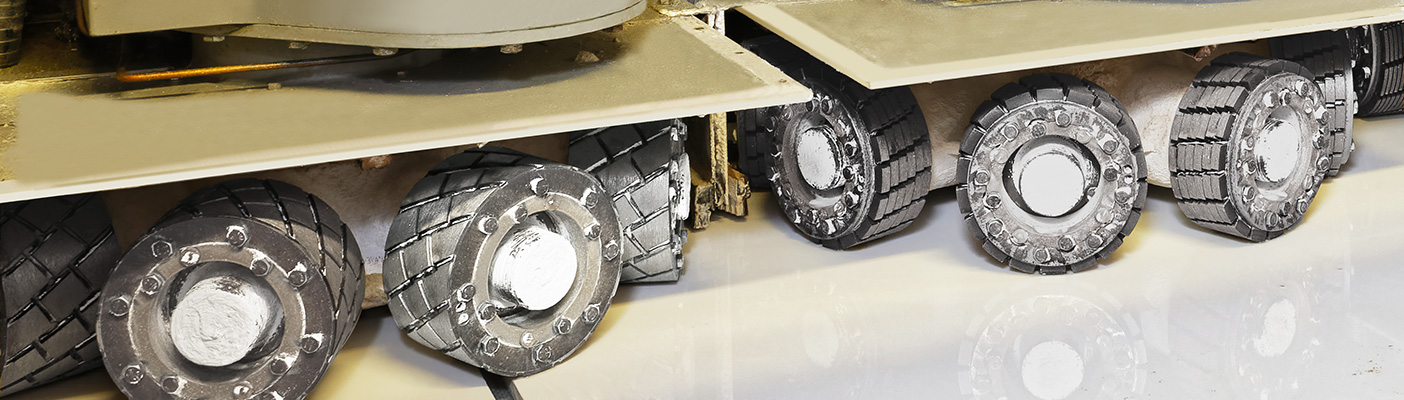

A fully operational pilot plant with all the exceptional know-how and assistance of Surfaces at your disposal.

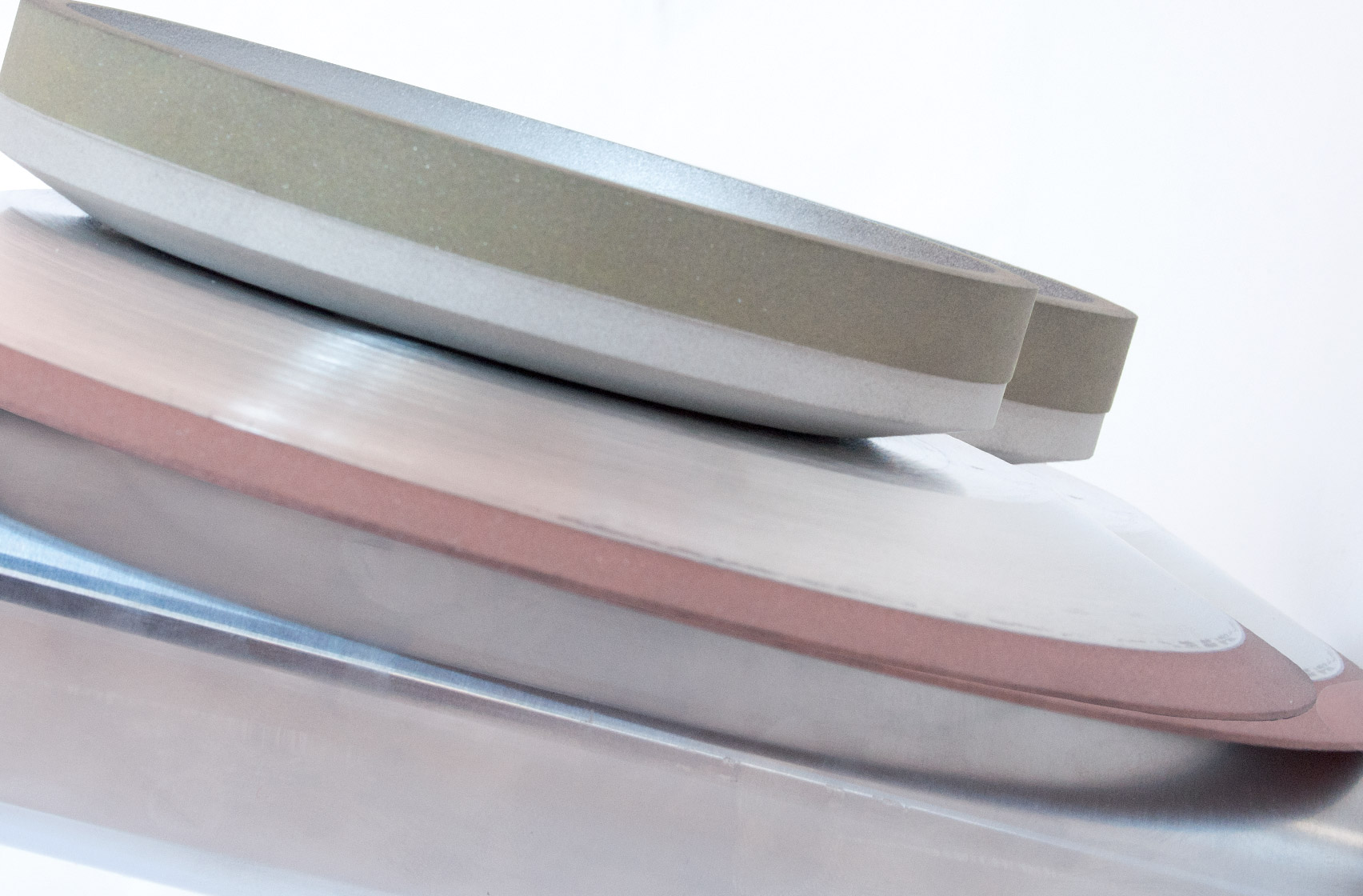

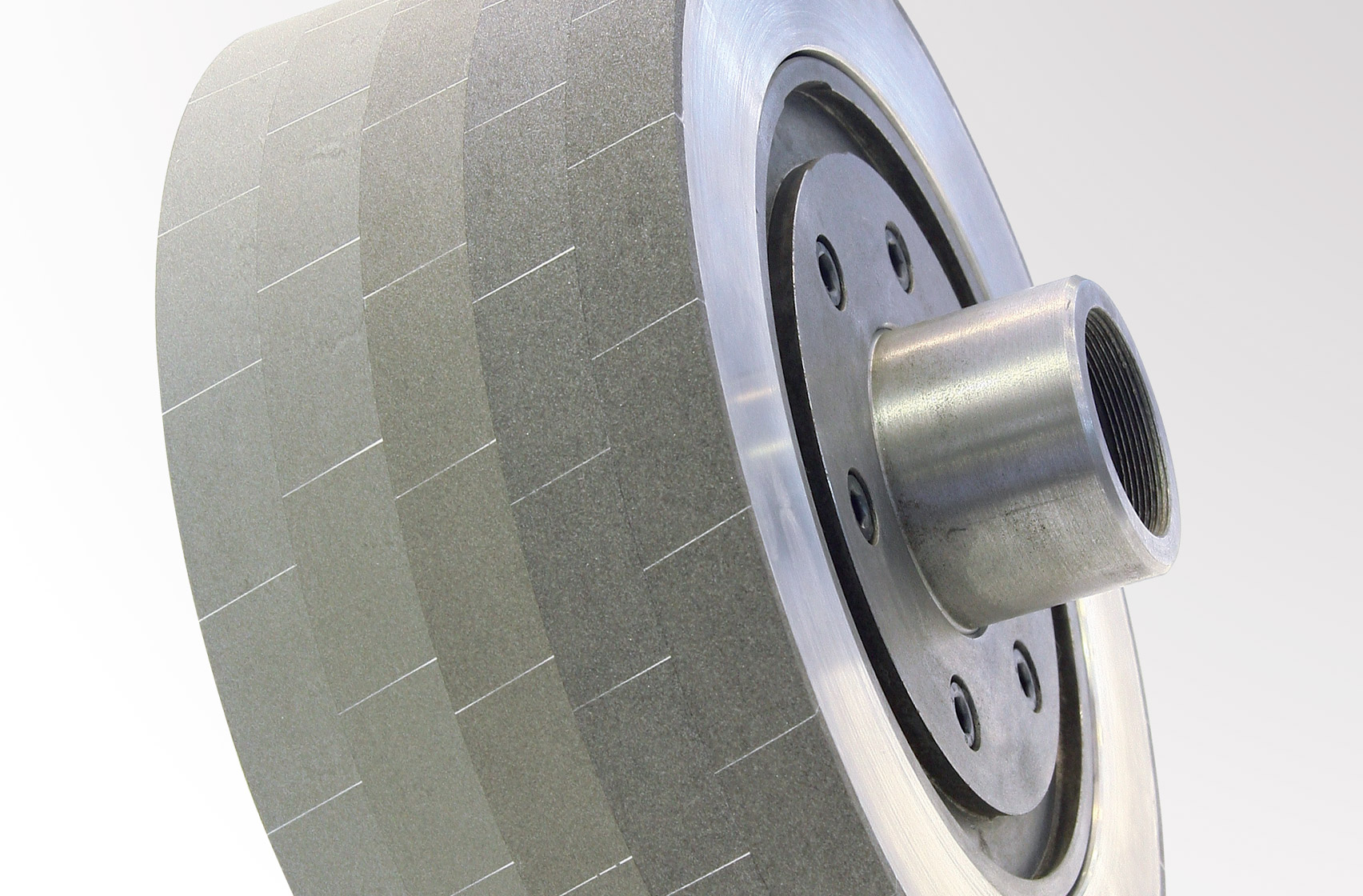

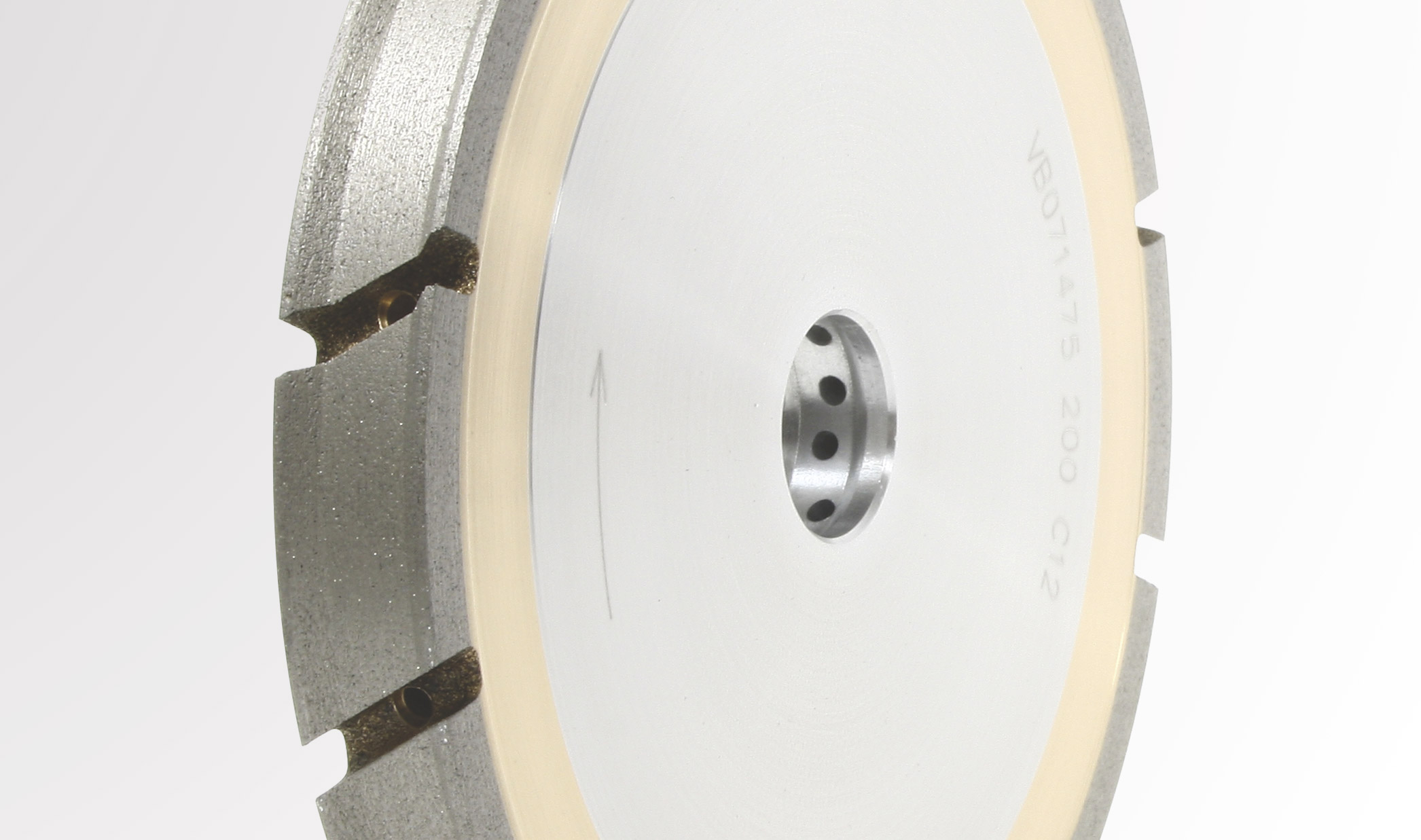

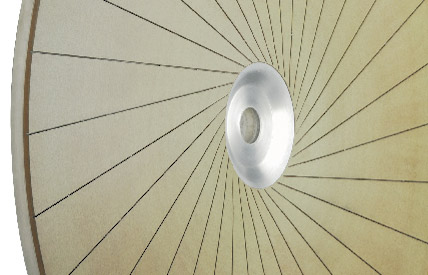

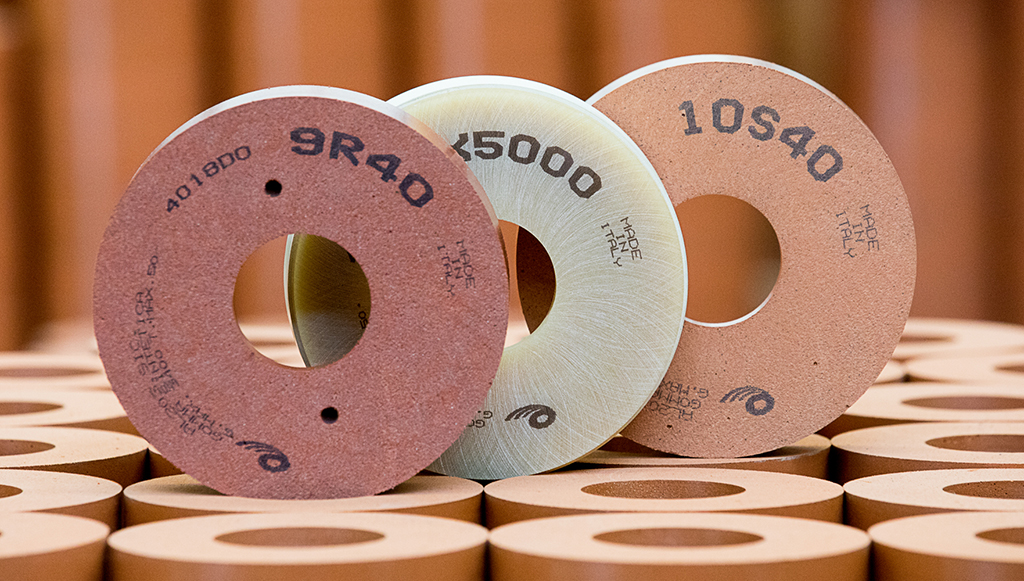

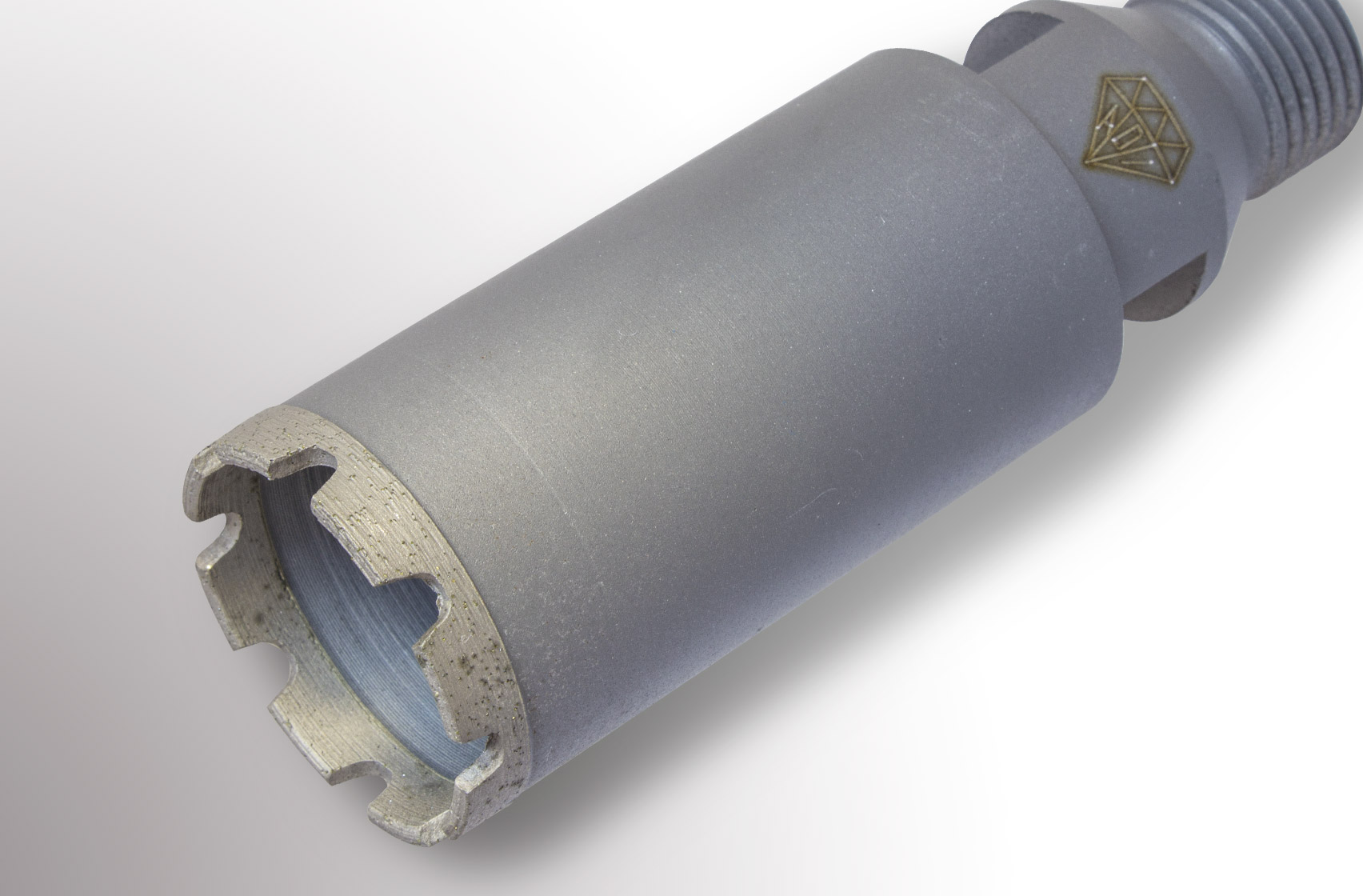

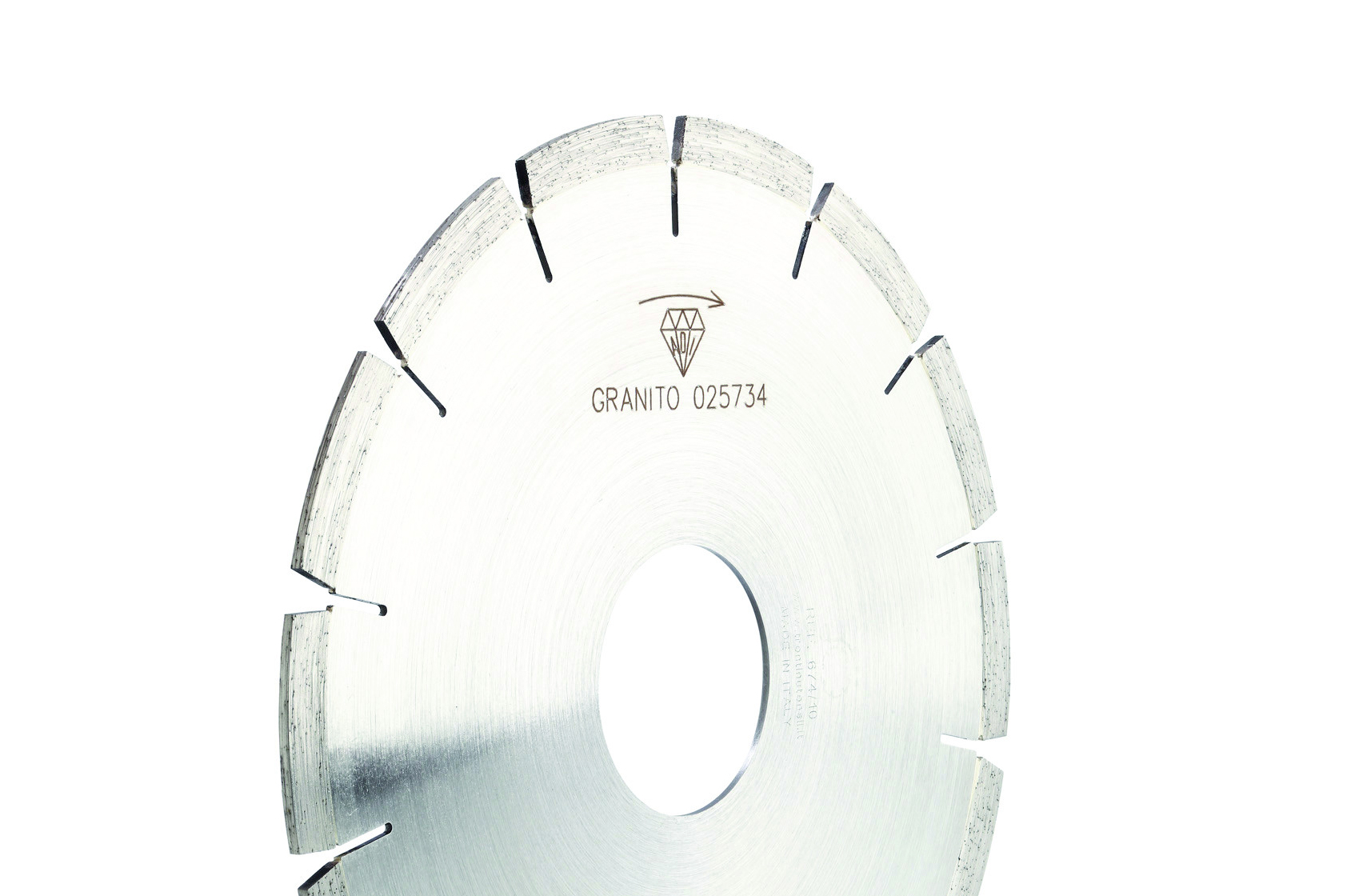

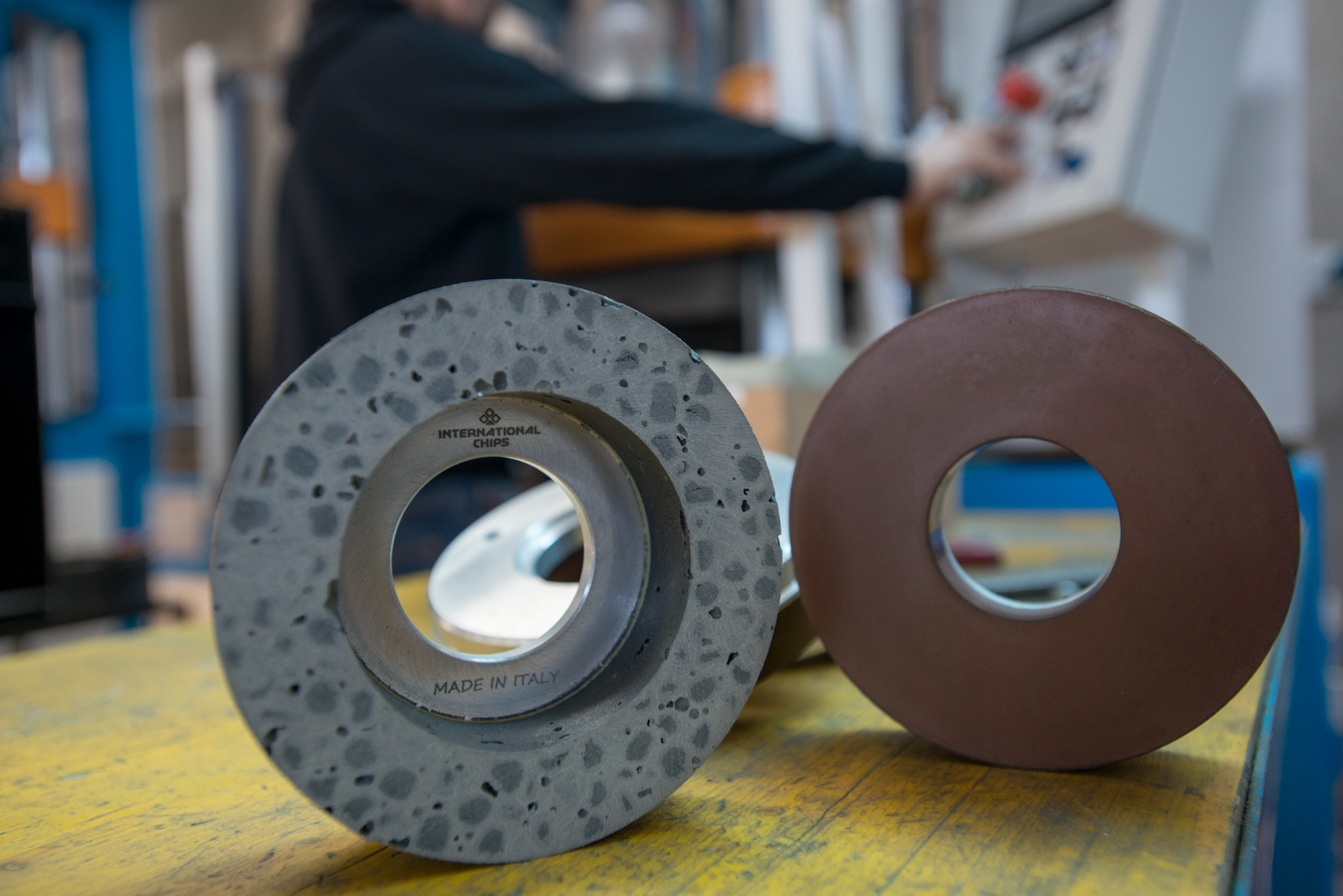

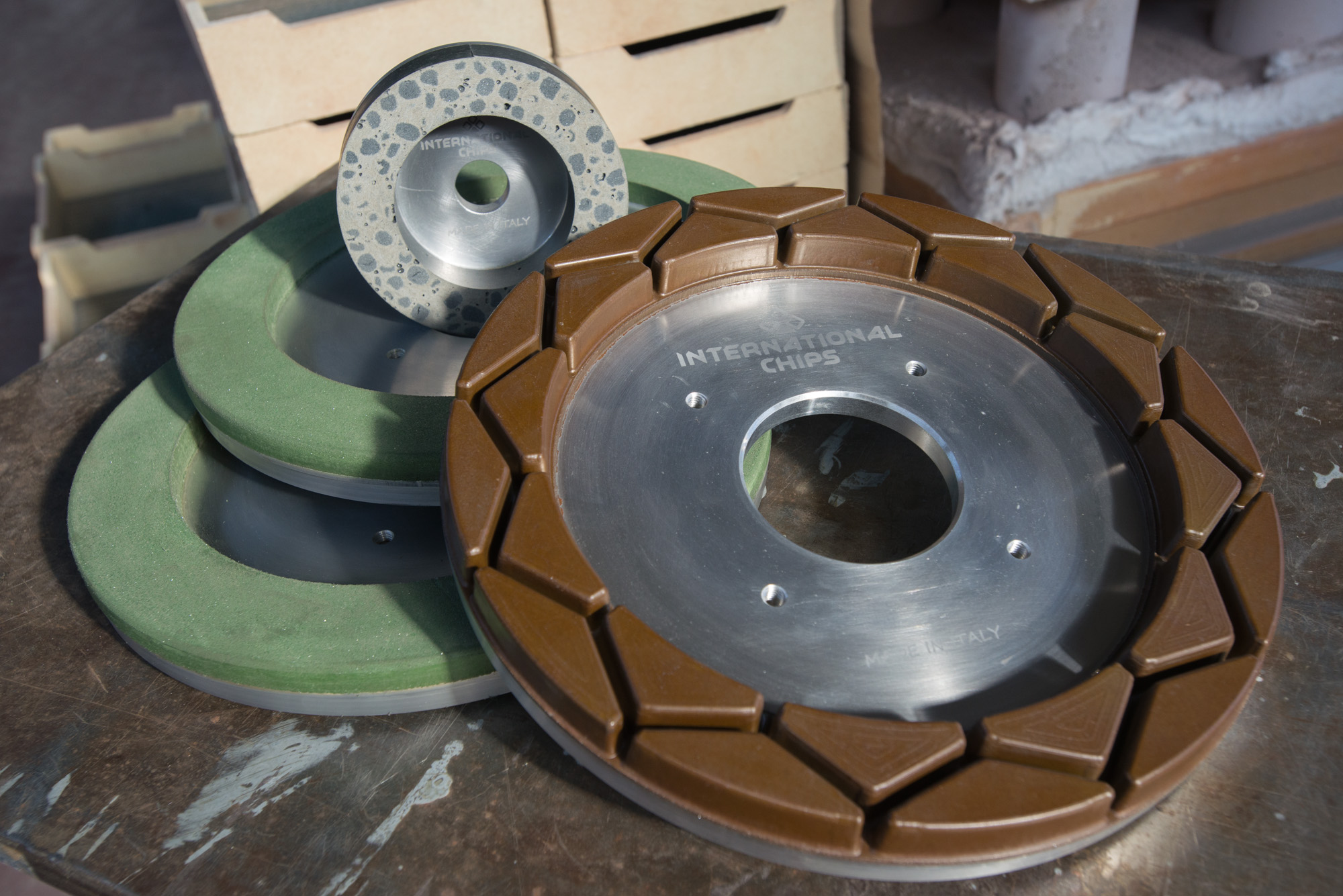

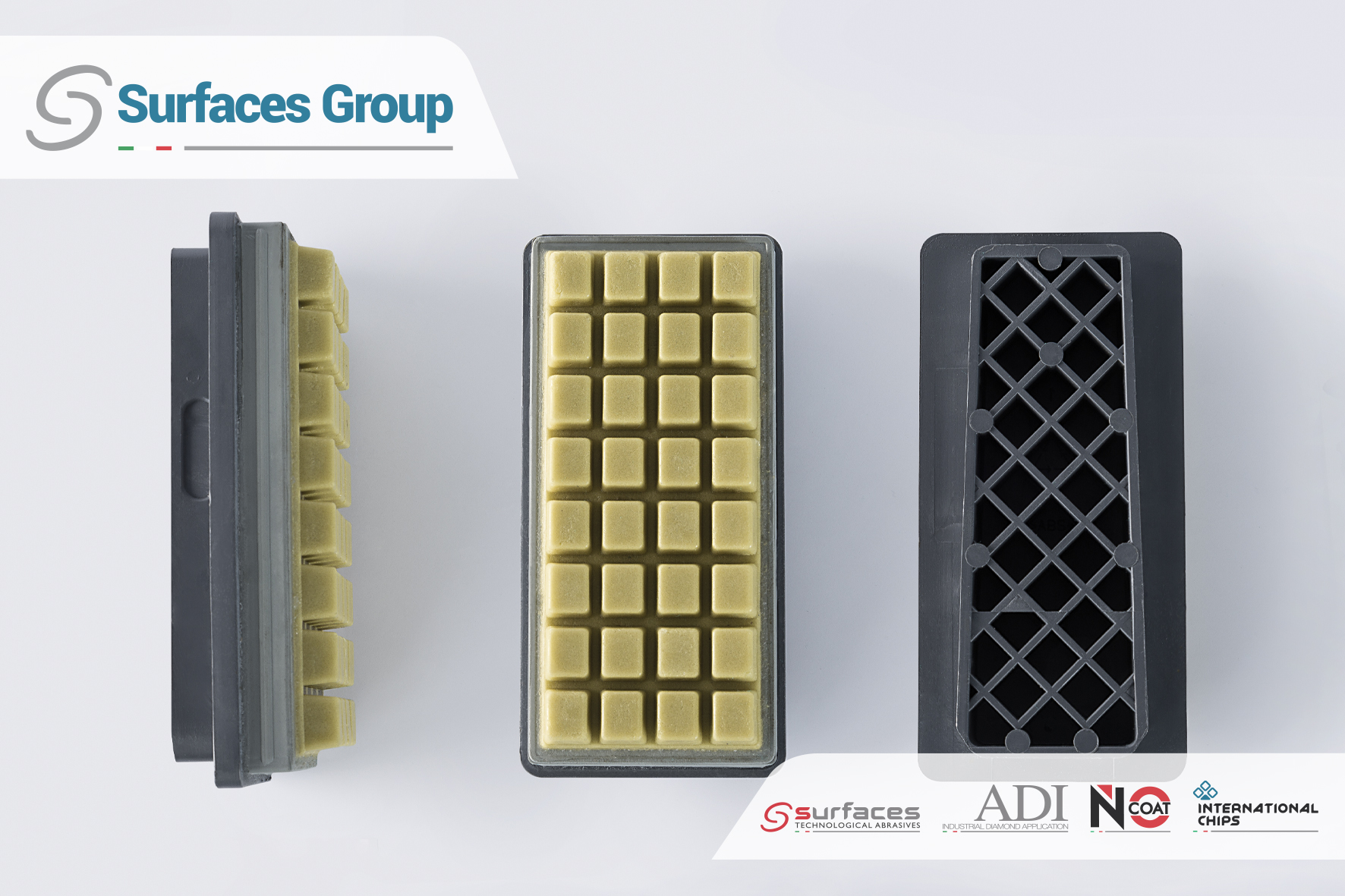

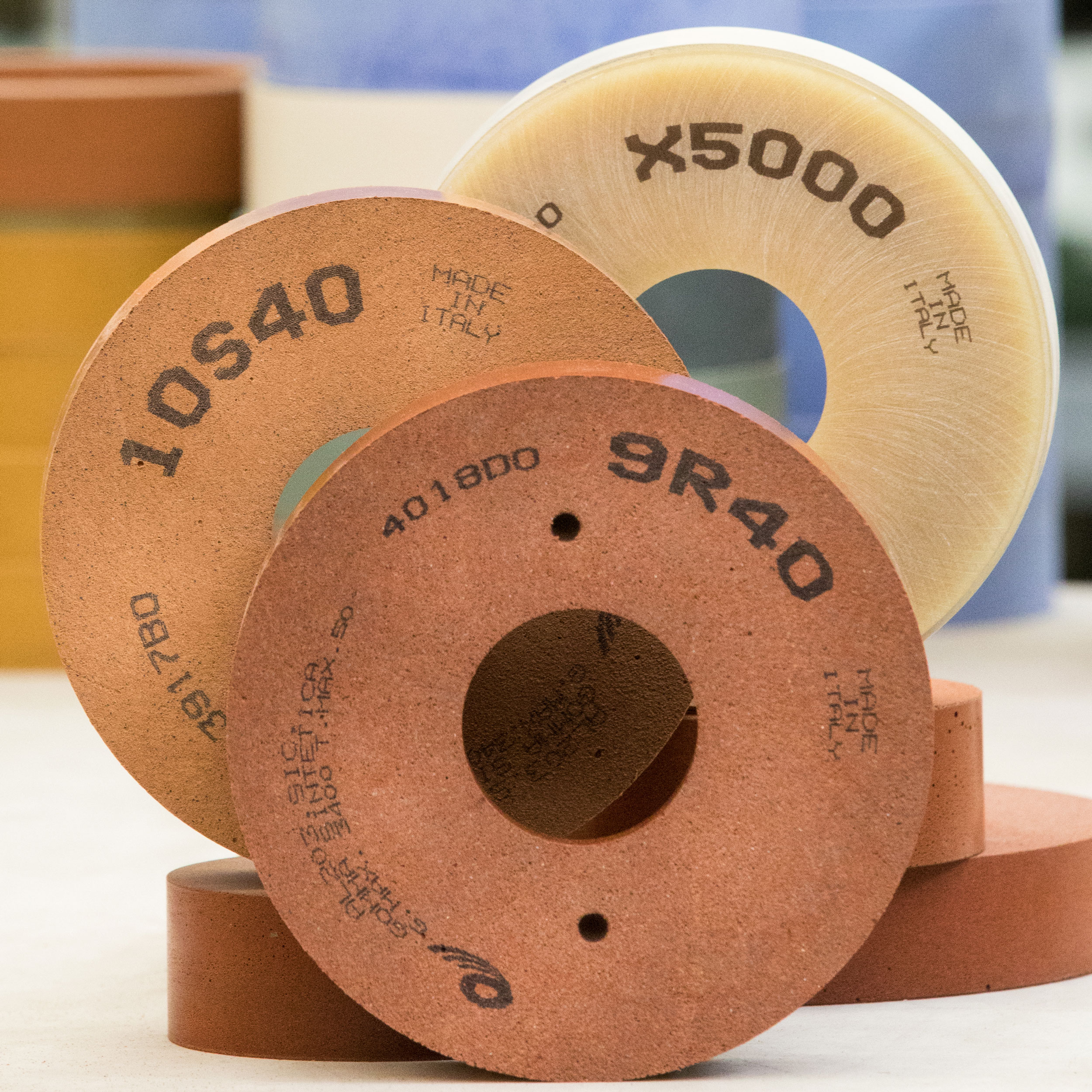

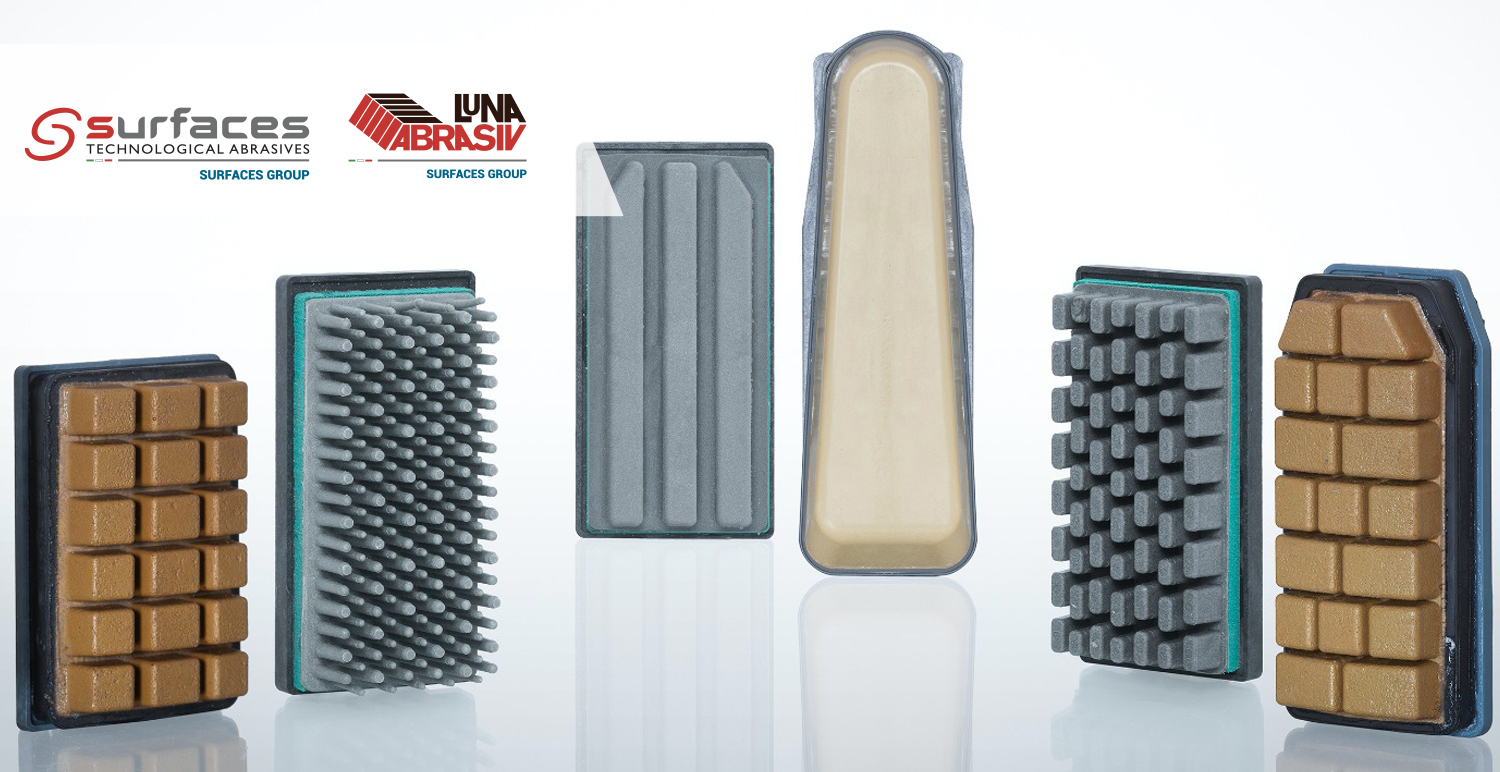

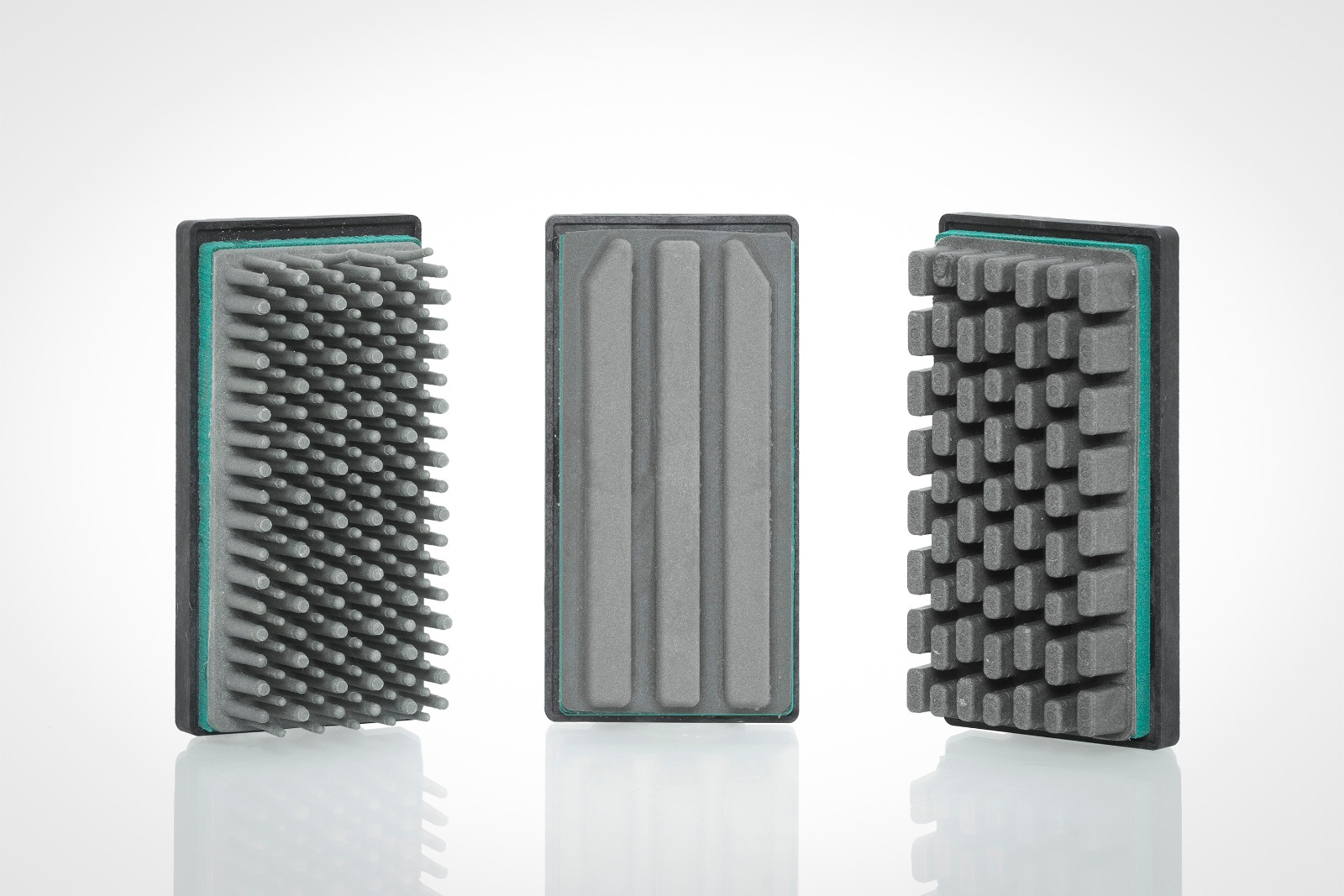

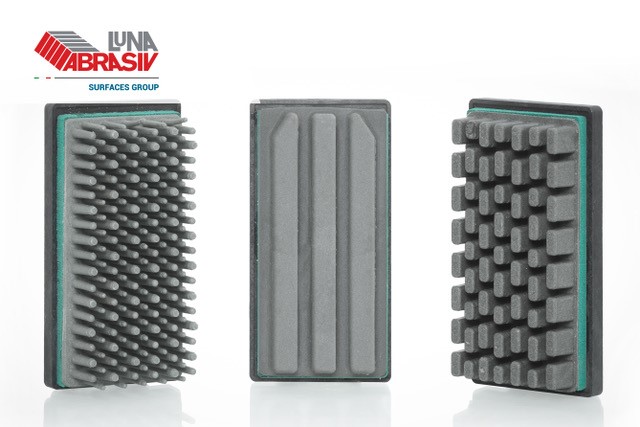

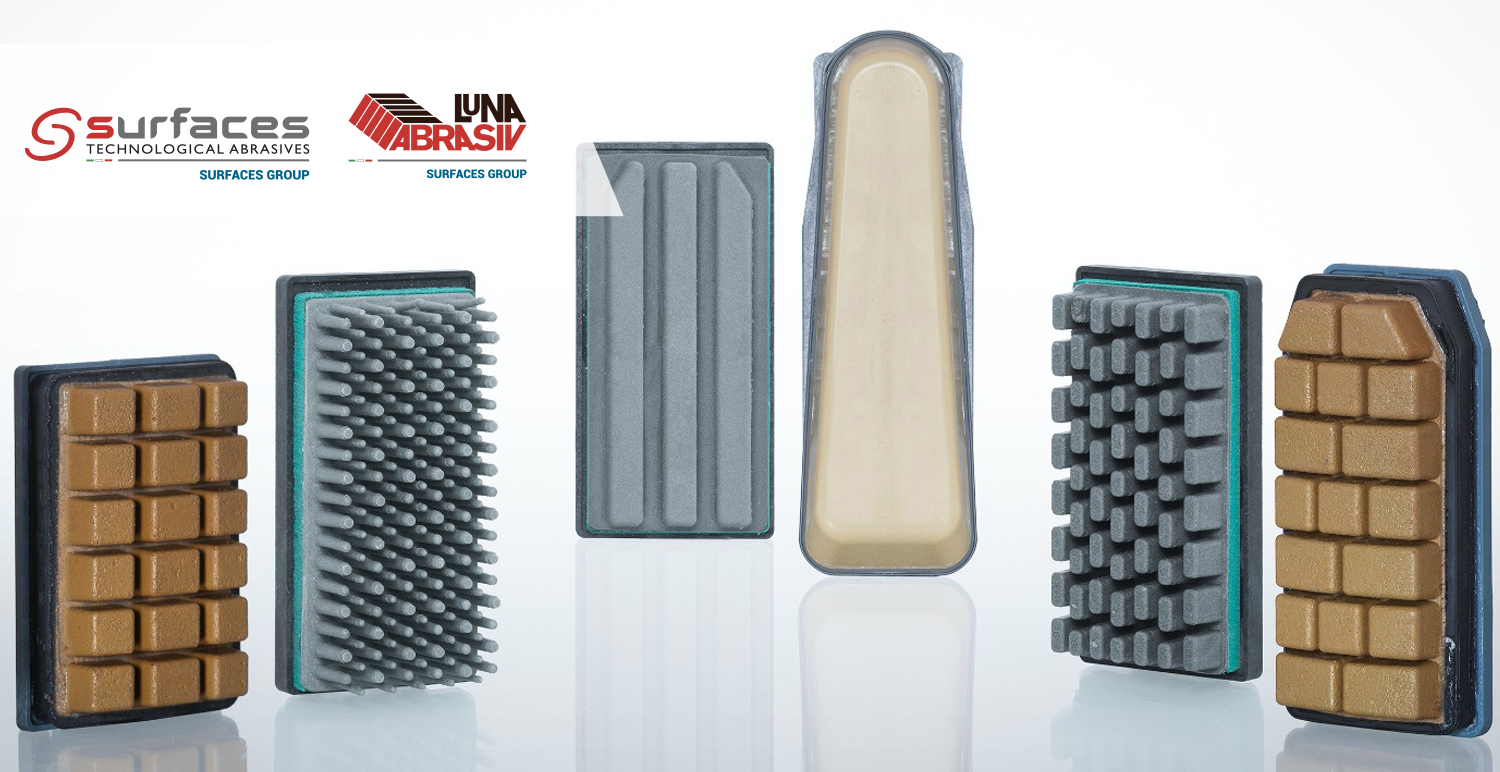

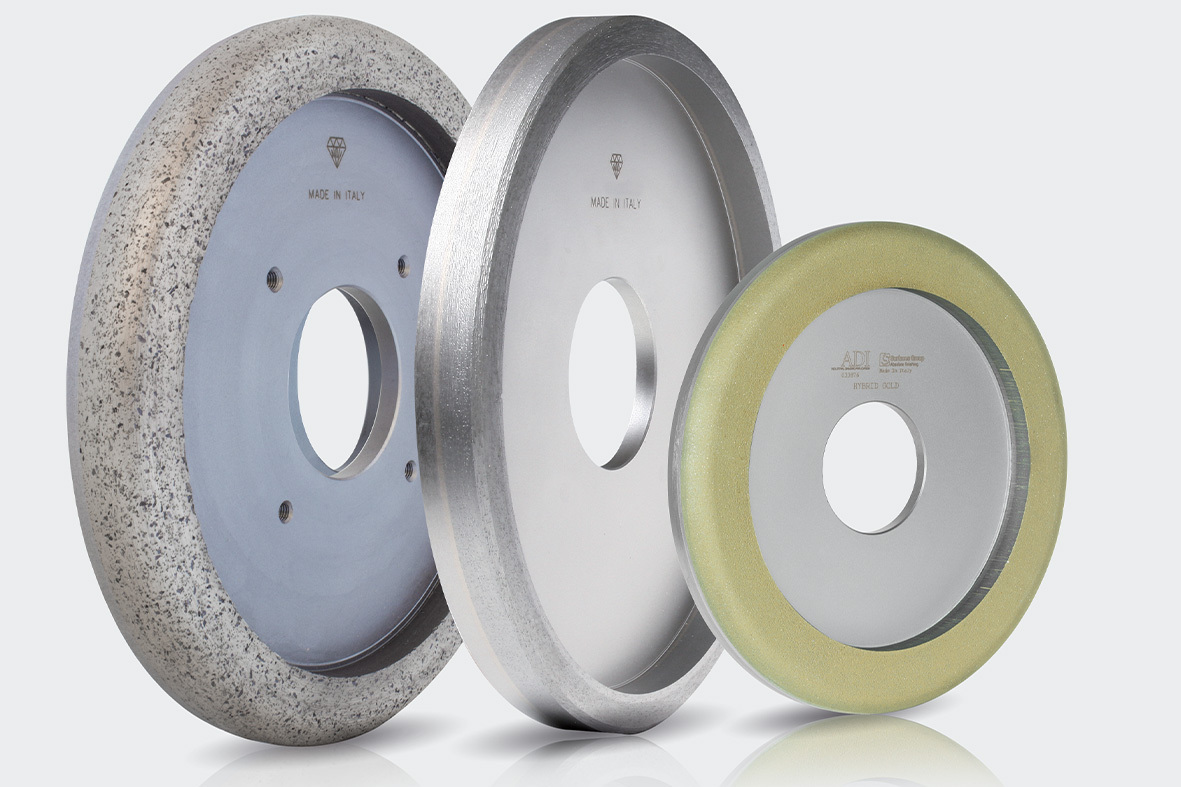

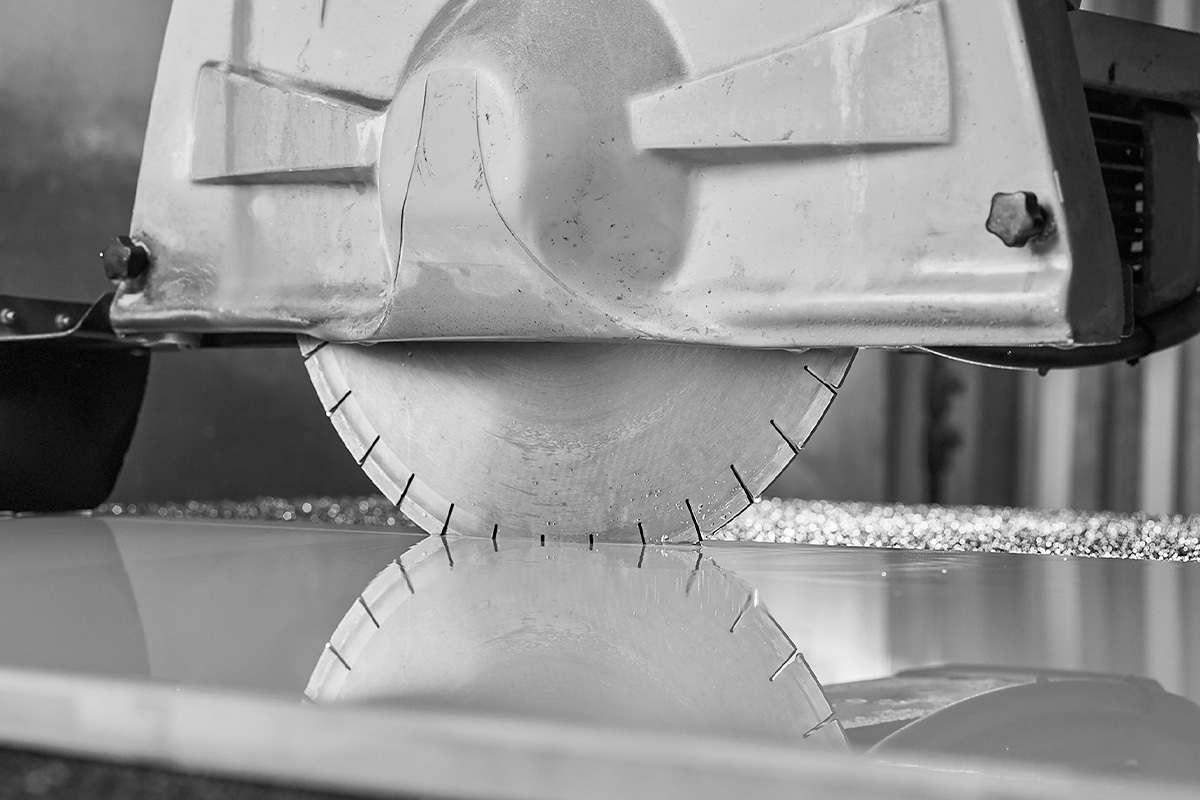

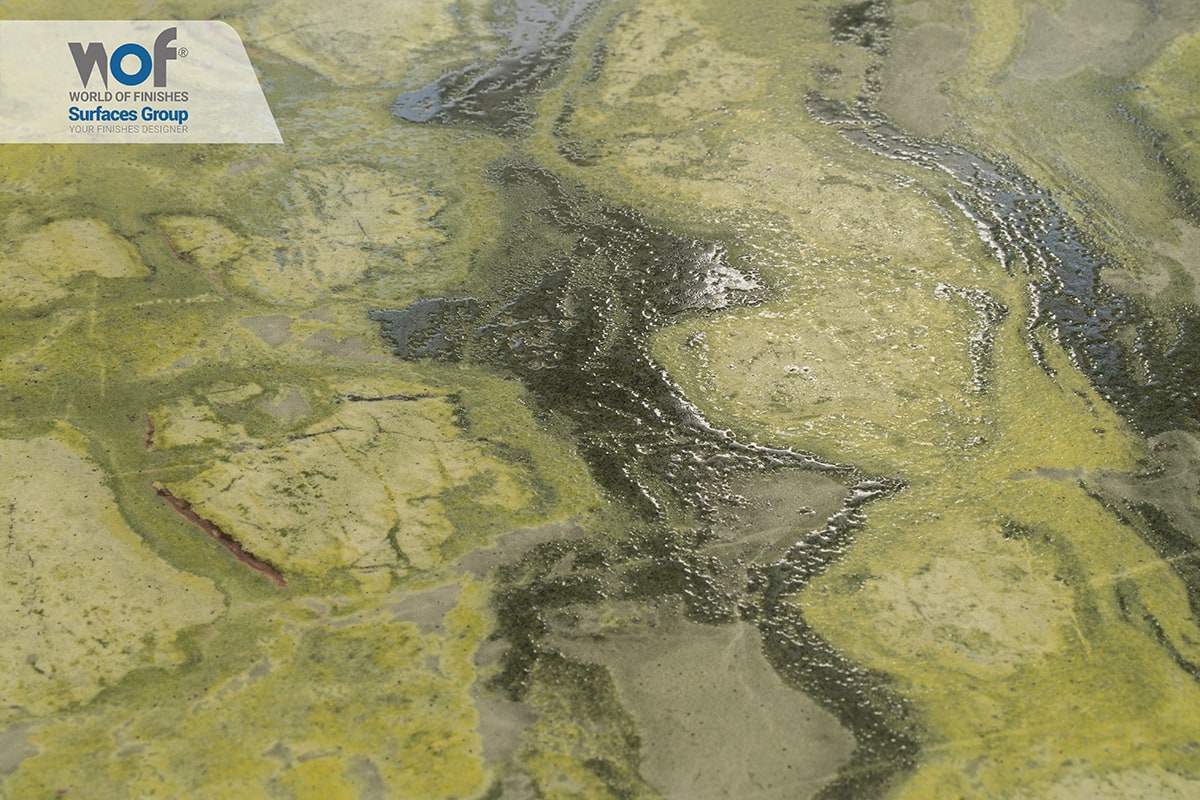

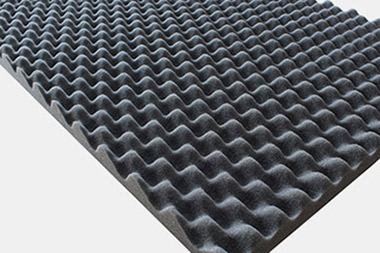

We study innovative and original solutions together, testing them on your product and defining the set-up for future series production. We carry out lapping with full lappato and lappato matt effects and an endless range of innovative solutions, including the final protective treatment and the associated technical tests.

SURFACES LAB

is a specific company department dedicated to research and set-up of new trials.

- A laboratory designed to facilitate your work.

- 100% customised solutions.

- More value for your product.

- Faster start-up of industrial production.

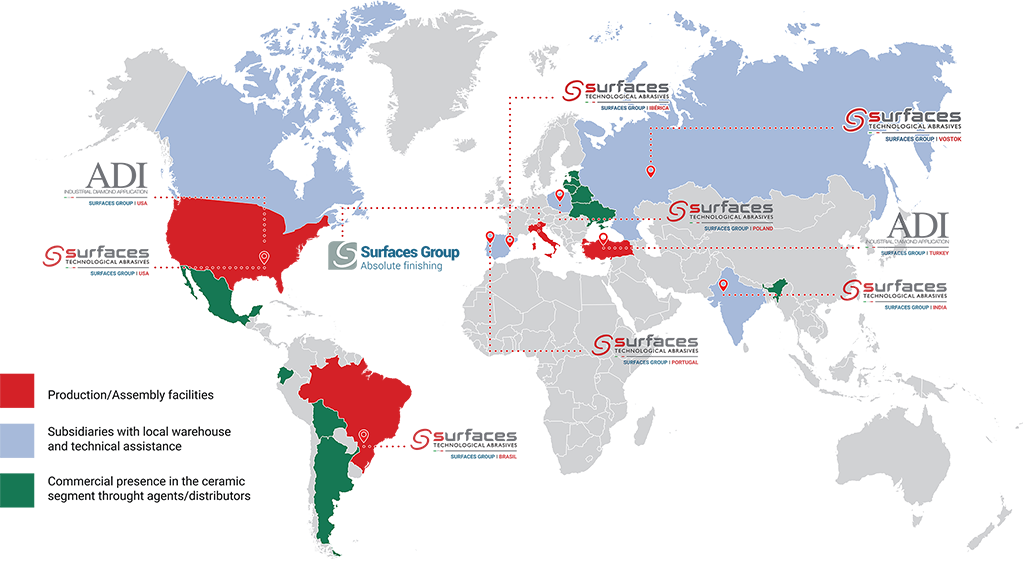

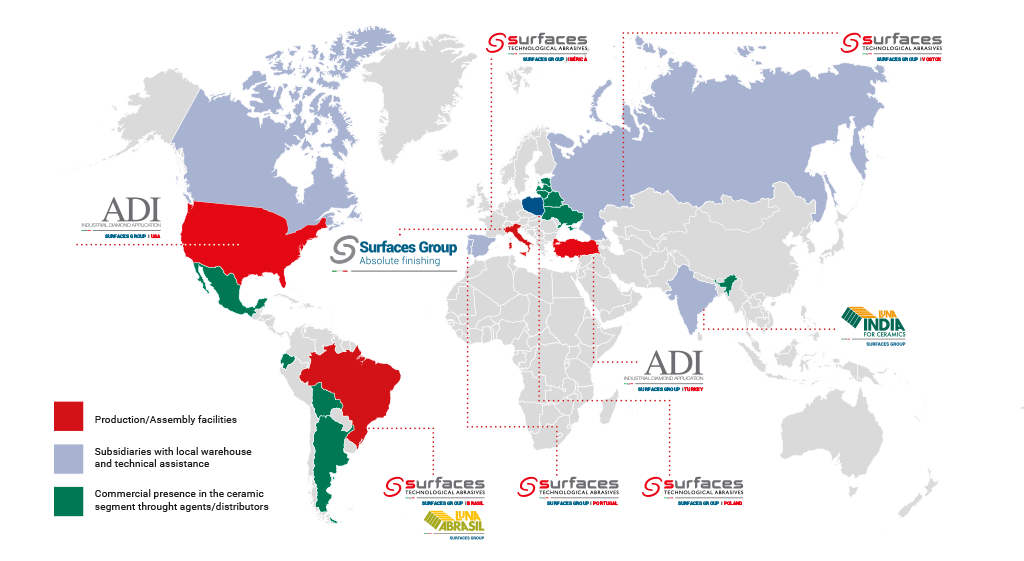

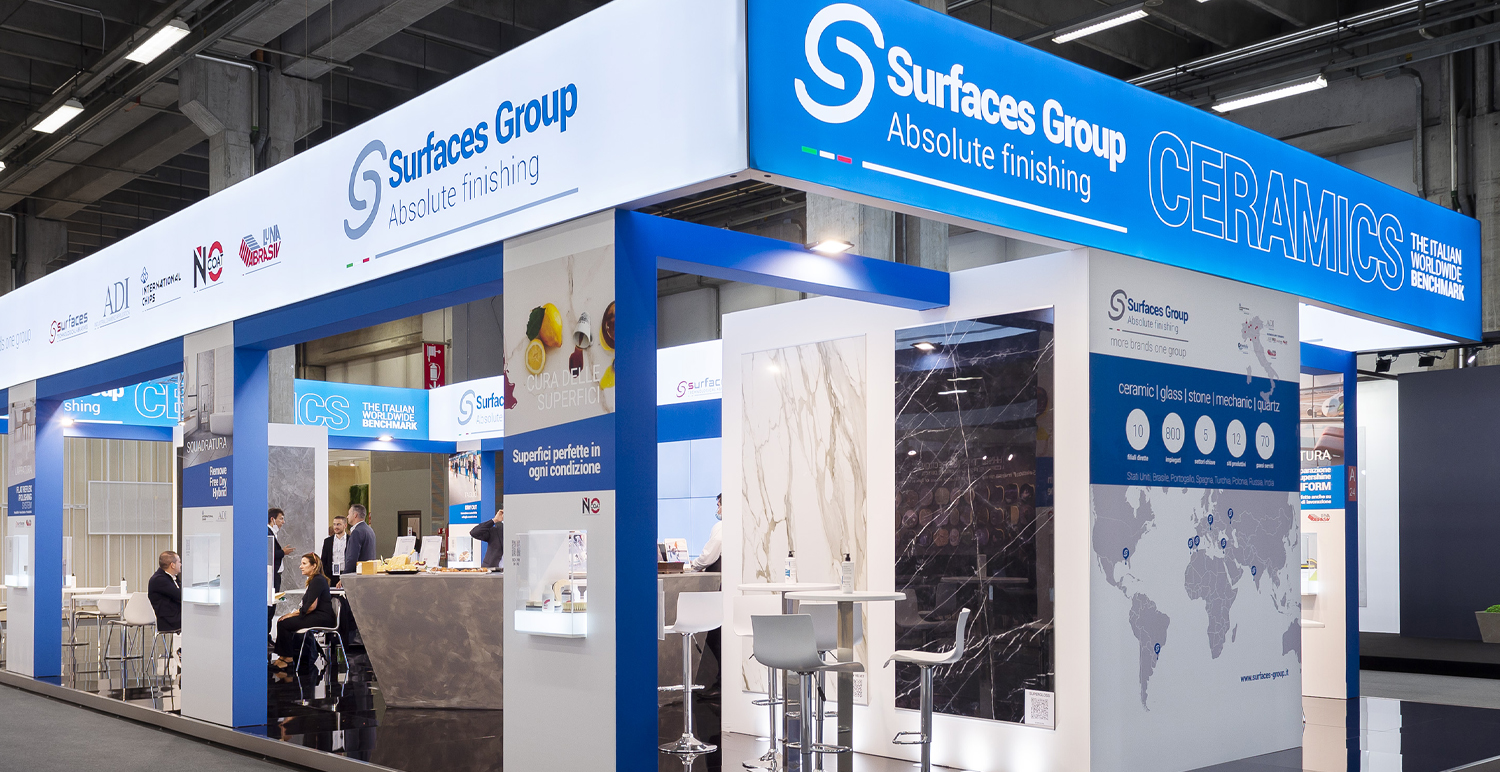

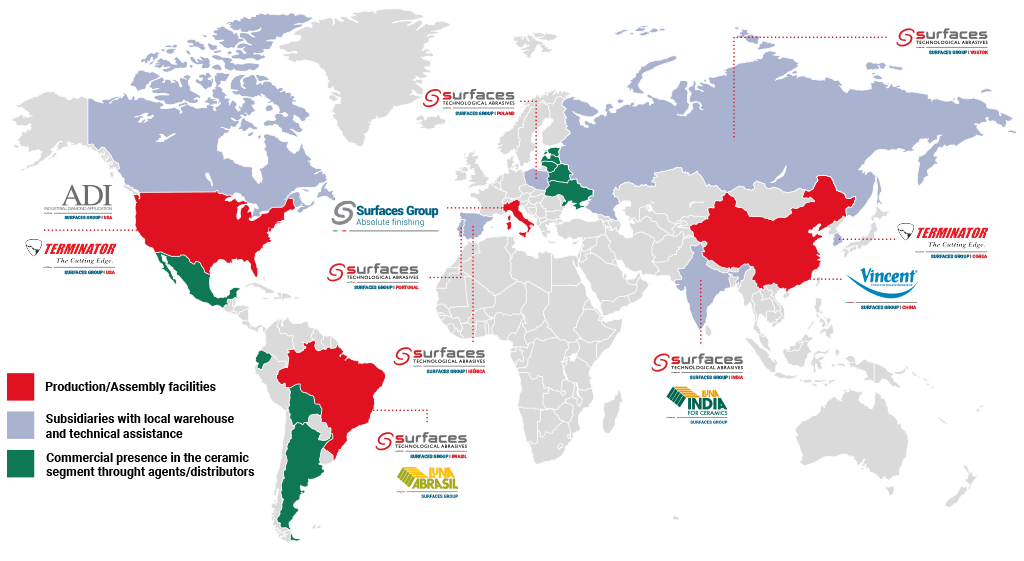

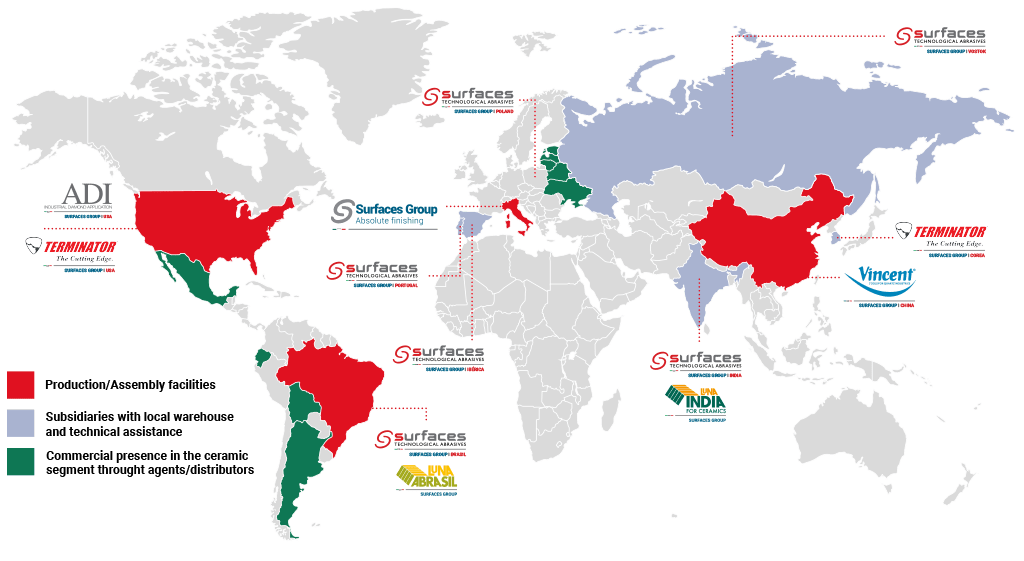

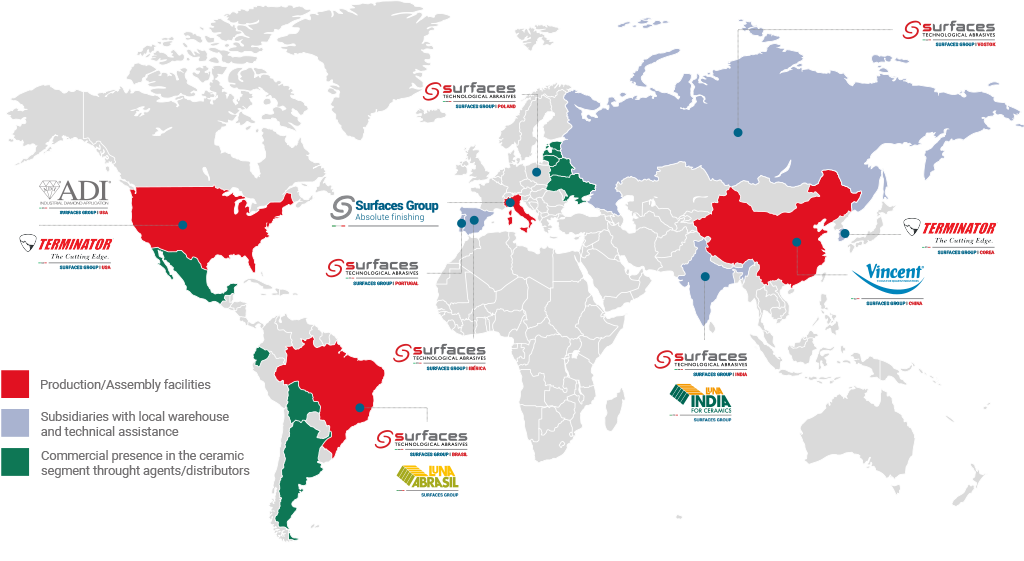

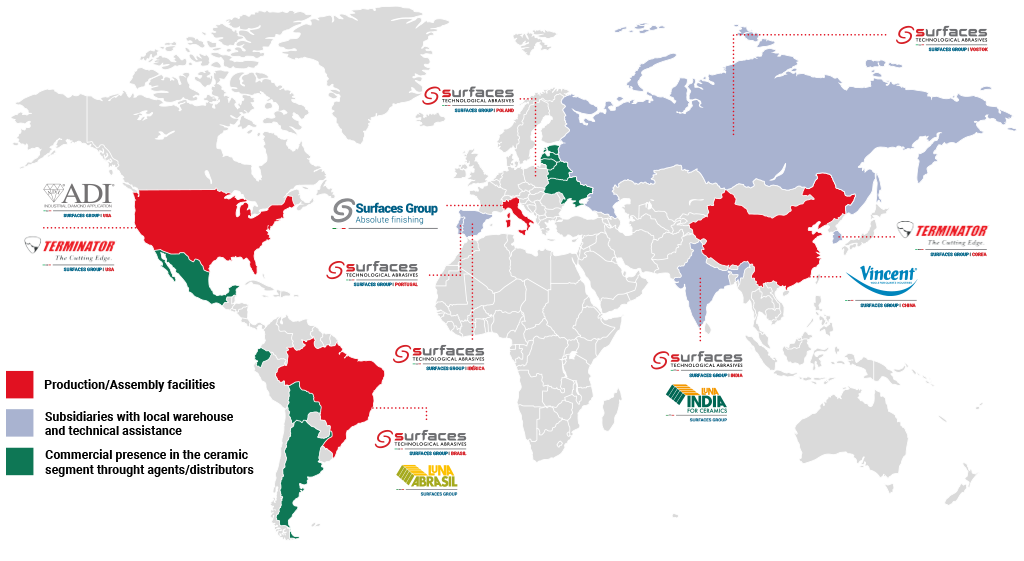

The process of innovation proceeds without ceasing in Surfaces Group. The need to facilitate the problem-solving process, shortening the times, monitoring the variables and reducing the margins of uncertainty, resulted in the decision to create a structure capable of reproducing the real working conditions on the line in a scale model. 2013 was the foundation year of Surfaces Lab, a plant staffed by engineers, chemists and senior technical specialists working together with the aim of developing and testing new integrated solutions: so not just new products, but new combinations of products.

But the function of Surfaces Lab doesn’t end here. The organisation’s experimental vocation and flexible structure are a precious resource for customer companies which, by entrusting the production of their samples of new ceramic products to our company, support the production departments in this delicate role, avoiding costly downtimes in series production operations.

The final frontier on which Surfaces Lab is active is that of treatments certification. Ceramic companies and the market are demanding additives that can protect glaze from stains, scratches or certain temperatures. Surfaces Group is highly acclaimed for the performance of its solutions in this field, but it was the first to face the certification question in relation to the additives. Surfaces Lab is therefore responsible for testing the retention of this performance through time in order to guarantee the aesthetic and functional properties of ceramic products through time.

HOW DOES THE SURFACES LAB PROGRAMME OPERATE IN PRACTICAL TERMS?

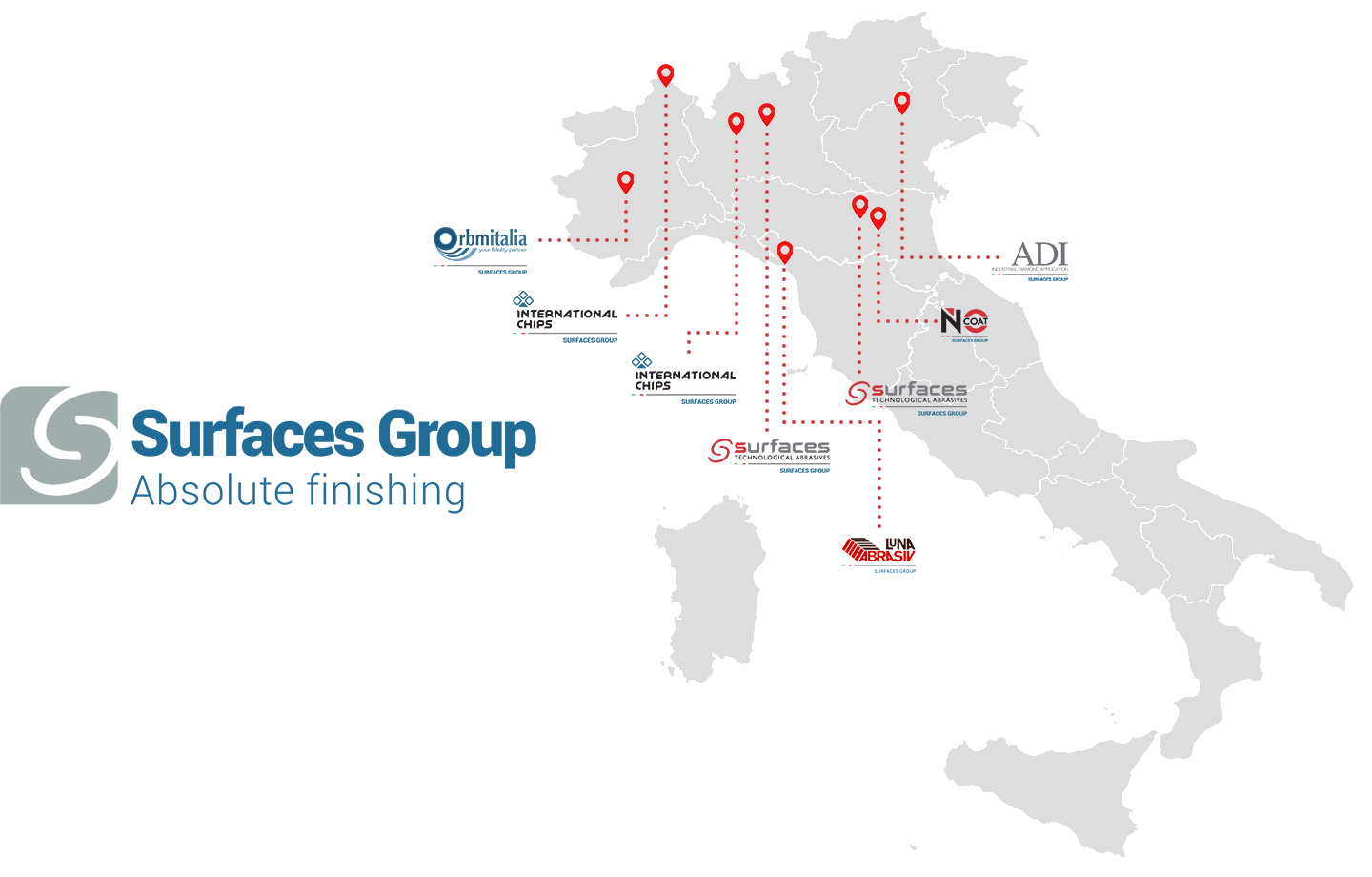

- Bring your prototypes to our Italian headquarters or one of our foreign branches

- We’ll work together to create a customised surface finish

- And we’ll deliver an exclusive and winning solution for your brand

2. We place our Surfaces LAB Pilot Plant at your disposal

- Innovative technology, highly qualified support and assistance

- Fine-tuning of set-up for industrial production

- Study of protective treatments

- Production of samples for trade events and catalogues

- An exclusive and customised surface finish

- Unparalleled aesthetic appearance of your product

- A top quality protective treatment

4. Additional benefits for industrial production

- Reduction of times and costs for the set-up of series production

- No plant stoppages to accommodate R&D activities

- Protective coating already defined and tested